Description

Extract/Refine up to 99.5% of gold.

100kg capacity gold refining plant using Aqua Regia process is a facility designed to refine and purify gold from various sources, such as scrap jewellery, bench work, filters, and even gold ore from mines. The Aqua Regia process is a chemical process that uses a combination of nitric acid and hydrochloric acid to dissolve and extract pure gold from impure materials.

The Aqua Regia process typically involves several stages of processing, including dissolution, filtration, and precipitation. During the dissolution stage, the gold-containing material is placed in a mixing tank with the Aqua Regia solution, which dissolves the gold and other precious metals. The resulting solution is then filtered to remove any impurities.

The next stage involves the precipitation of the gold from the solution. This is typically done by adding a reducing agent, such as sodium metabisulphite, to the solution, which causes the gold to precipitate out as a fine powder. The gold powder is then washed and dried to remove any remaining impurities.

After the gold has been precipitated and dried, it is melted down into bars or ingots using a furnace or other melting equipment. The resulting gold bars or ingots can then be sold or further processed for use in the jewelry or investment industries.

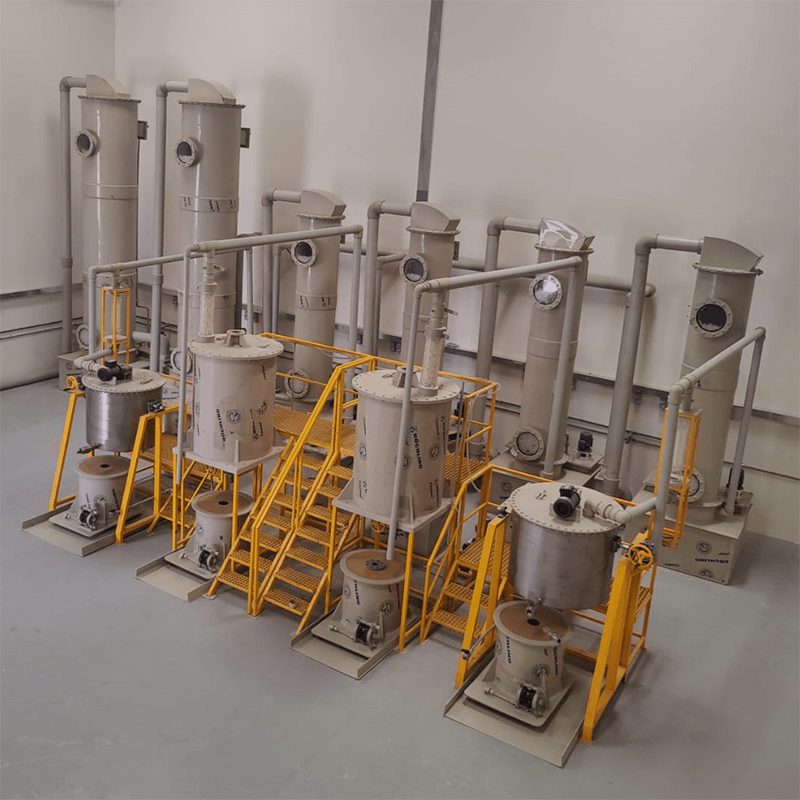

Refining plant typically includes several key components, such as chemical mixing titanium tanks, scrubbers, filters, and heating and cooling systems. The plant is designed to be fully automated, with computerized controls and monitoring systems to ensure precise and accurate processing.

Another essential component of the refining plant is the filtration system. The filters are designed to remove any remaining impurities or solids from the solution, leaving only the pure gold behind.

The drying and melting systems are also critical components of a gold refining plant that uses Aqua Regia process. The drying system is used to remove any remaining moisture from the purified gold, while the melting system is used to melt the purified gold into bars or ingots for shipment or further processing.

In summary, a gold refining plant with a 100kg capacity that uses Aqua Regia process is a complex facility designed to extract and purify gold from various sources. The plant includes a range of chemical and mechanical systems and is designed to meet strict safety and environmental regulations. With proper design and operation, this gold refining plant can provide a reliable and profitable source of pure gold for the jewelry and investment industries.